When transporting highly specialized cargo, even the smallest delay can jeopardize an entire project. This reality shaped the challenge faced by deugro, which was tasked with delivering 15,500 tons of subsea cable from ports in Japan and Norway to a cable-laying vessel in Abu Dhabi. Working on behalf of Samsung C&T, the shipment was critical to the timely installation of high-voltage direct current (HVDC) submarine cables for an electrification project offshore Abu Dhabi.

Flawless Coordination Across Continents

The cables—stretching a combined 700 kilometers—had to arrive precisely on schedule to prevent costly downtime for the installation vessel. deugro mobilized its teams in Korea, Japan, and the UAE to execute a tightly synchronized operation.

“Each operational phase depended on the previous one being completed on time. A delay in one location could have disrupted the entire supply chain,” said Jong-Yub Han, Sales & Business Development Manager at deugro Korea.

To meet tight timelines, deugro and Samsung C&T agreed on a comprehensive end-to-end logistics plan that included vessel chartering, inspections, coordination with contractors, scheduling, and technical support.

Precision Loading in Japan and Norway

The first shipment originated in Osaka, Japan, where 140 kilometers of multi-core round cable (MRC) were loaded onto the heavy-lift vessel UHL Falcon. Before departure, deugro’s team had to react quickly to a short-notice requirement from the Maritime Warranty Surveyor: recording acceleration data during the voyage. With no onboard monitoring system available, deugro rented and hand-carried a system to Osaka for immediate installation.

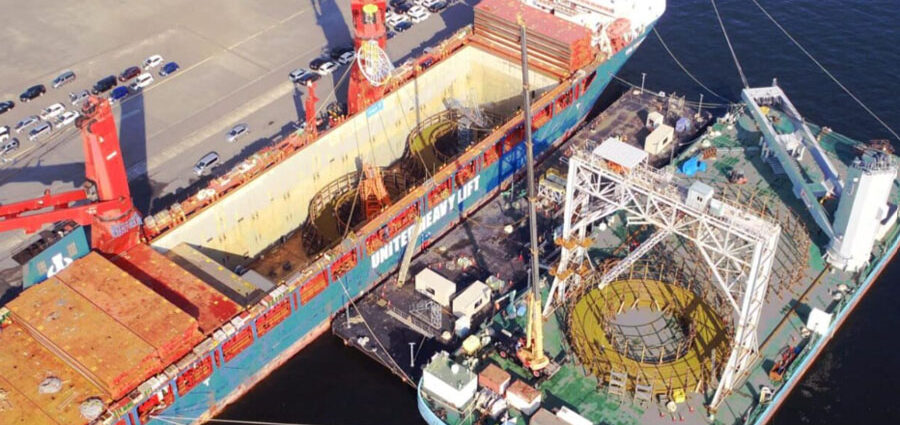

Additional shipments followed at the Port of Hitachi, where two United Heavy Lift vessels—UHL Force and UHL Fierce—each loaded 140 kilometers of DC400kV cable.

The final batch of 280 kilometers of fiber-optic (FO) cable departed Norway aboard BBC Chartering’s BBC Austria. Originally, the plan called for loading fully spooled baskets, but the jetty could not support the weight. Instead, empty baskets were loaded, and the cable was spooled directly onboard.

Handling these subsea cables demanded extreme precision. With strict parameters for bending diameters, pulling forces, crush loads, and more, every step required specialized expertise.

Critical Operations in Abu Dhabi

Upon arrival in Abu Dhabi, the MRC and DC400kV cables were transloaded onto Jan De Nul’s Isaac Newton—the world’s largest cable-laying vessel, capable of carrying 10,500 tonnes in a single trip. Securing such a vessel is one of the most time-sensitive elements in project logistics, as delays can result in millions in idle costs and missed weather windows.

The Isaac Newton acted as the “master unit” during transpooling, synchronizing speeds across the carousel, bow cable engine (BCE), and multiple linear cable engines (LCEs). Perfect alignment was essential to prevent tension imbalance or cable damage.

Meanwhile, the FO cables were discharged and stored onshore until ready for loading, a more flexible process due to their lighter construction.

Final Phase: Static Tank Disposal

After cable delivery, deugro was also responsible for dismantling and disposing of the large steel static tanks used to transport the cargo. Working with AD Ports Group, port authorities, and contractors, a 40-person team completed the removal within four days—well within vessel laytime limits.

A Seamless Global Operation

Reflecting on the project, Nils Sauerborn, Director of Offshore Solutions at deugro, said the operation demonstrated the power of cross-regional collaboration.

“By combining our technical knowledge with precise planning and execution, we ensured that every stage met the highest standards,” he noted. “It’s a great demonstration of what we can achieve together for our clients.”