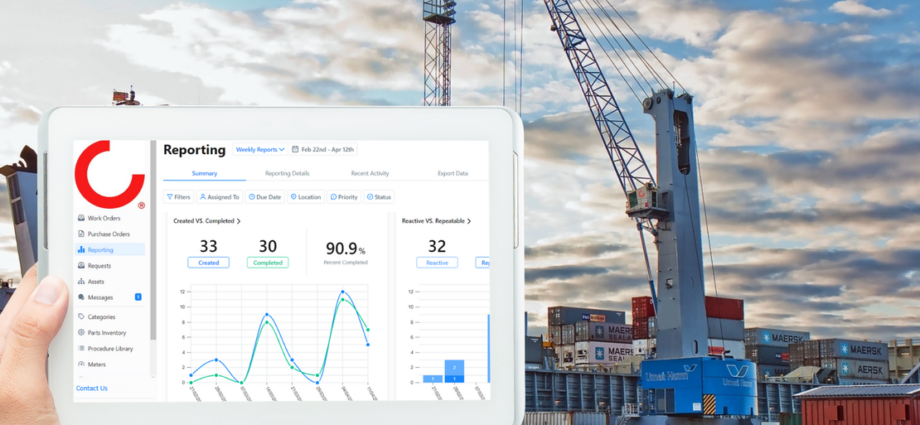

Konecranes South Africa has taken a major step in digitalising crane maintenance with the launch of its Konecranes Portal, a single access point for customers to monitor crane performance, maintenance history, and asset data.

“Issues like downtime, safety risks, and equipment performance cannot be properly addressed without accurate data,” says Ian Grobler, Sales Manager for Konecranes South Africa. “Our portal allows customers to make informed decisions by providing real-time insights into their assets and maintenance records.”

Informed Maintenance Decisions

The portal incorporates Konecranes’ Risk and Recommendation Method, documenting component exceptions during service visits, assessing risks, and providing actionable recommendations to improve safety and productivity. Technicians upload service data via mobile devices, giving customers instant access to inspection reports and maintenance logs.

Asset Monitoring and Spare Parts

Registered users can view their crane and hoist assets in real time via Truconnect Remote Monitoring, which displays safety and production risks in colour-coded alerts and component condition in easy-to-read graphs. Customers can also browse and order spare parts, manuals, and accessories for multiple brands, models, and equipment types directly from the portal.

The portal’s Store page allows users to search product categories, access quick links, or explore generic manuals and spare part catalogues specific to their equipment models.

Safety and Compliance

The portal includes a Slings and Inspection facility designed for inspecting non-maintainable load-lifting attachments. Using RFID tags and a smartphone app, Konecranes tracks inspection data, identifies deficiencies, and ensures compliance with local safety regulations. The system automatically schedules audits and replacements and prioritises devices approaching or past due inspection dates, helping customers avoid safety risks.

Remote Service and Performance Monitoring

Through the Truconnect suite, customers can access Remote Monitoring, Brake Monitoring, and Wire Rope Monitoring, enabling analysis of anomalies, patterns, and trends that inform maintenance planning. Technicians upload inspection, servicing, and repair data in real time, facilitating cost tracking, budget planning, and performance reporting.

Data-Driven Performance

“Without measurement, there is no data; without data, there is no indication of performance or condition,” Grobler explains. “Our portal ensures that usage, wear and tear, and performance metrics are captured accurately, supporting data-driven maintenance and extending the lifespan of lifting equipment. It is an essential tool for both customers and technicians, fostering a closer partnership and optimising operational efficiency.”

The Konecranes Portal positions the company at the forefront of digital maintenance solutions, combining asset visibility, safety compliance, and data-driven decision-making in a single, user-friendly platform.