Maintaining conveyor belt cleanliness is more than a routine task—it’s essential for operational efficiency and safety. Excessive carryback can reduce belt and component life by up to 30%, yet the cost of implementing a multiple belt cleaner system often represents less than 5% of total belt wear, delivering substantial benefits.

The Importance of Effective Maintenance

Proper monitoring and servicing of belt cleaners are critical to conveyor safety. Buildup from inadequate cleaning increases the risk of accidents, as workers may be exposed to moving belts during manual cleaning. Achieving optimal performance, however, requires both knowledge and skill. Many leading manufacturers provide factory-trained personnel and replacement components to ensure belt cleaning systems operate efficiently and safely, extending the service life of all components.

Safe Service Practices

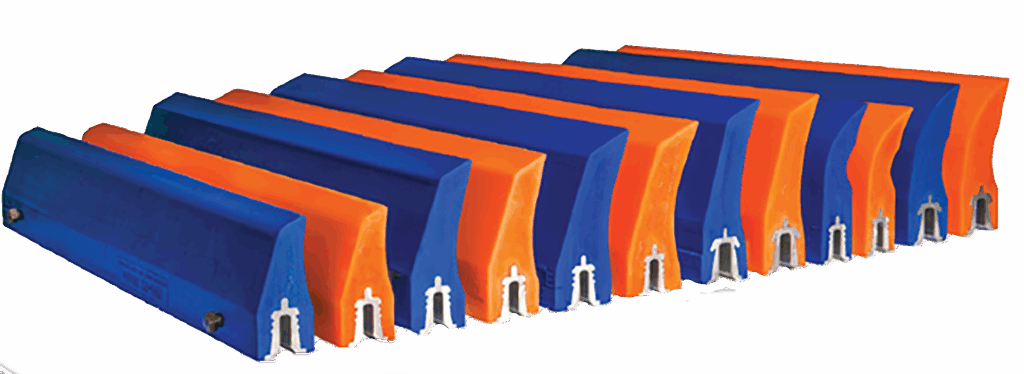

Experts recommend installing two or more cleaners per discharge point—primary, secondary, and tertiary. This not only enhances cleaning efficiency but also adds redundancy, extending service intervals. Matching the blade material to the specific application is crucial to maximizing performance and longevity.

Maintenance involves tasks such as adjusting tensioners, removing buildup, cleaning spillages, and replacing worn blades. Almost all service activities should follow strict lockout, tagout, blockout, and testout (LO/TO/BO/TO) protocols to ensure safety.

Understanding Blade Performance

While it may seem logical to increase cleaning pressure when a system underperforms, this can actually worsen blade wear. Skilled service technicians understand how to adjust cleaner types, blade materials, and cleaning pressures for seasonal variations or differing ROM (run-of-mine) conditions.

Some advanced designs, such as Cleanscrape, require minimal maintenance after installation. Featuring diagonally installed tungsten carbide scrapers forming a three-dimensional curve around the head pulley, these systems can achieve up to four times the service life of traditional urethane cleaners.

Monitoring and Automation

Modern monitoring solutions track blade wear and communicate maintenance needs via Wi-Fi or cellular networks. Mobile apps and dashboards notify maintenance staff of upcoming service requirements or adverse conditions, reducing the need for frequent physical inspections and allowing staff to focus on other tasks.

Martin’s N2® Position Indicator, for example, helps communicate system status to maintenance teams, improving both safety and efficiency. Choosing a supplier with experienced service technicians and considering managed service programs can further enhance productivity, lower operational costs, and ensure safer working conditions.